The fate of an

individual

„Each individual victim of climate change is one victim too many. Natural disasters have made vast swathes of land uninhabitable. Hundreds of millions of people have been forced to leave their homes. Simply looking on is of no help whatsoever. The will must be there to change the situation. And that’s exactly what we’re doing.“

Romina

With our help, production cycles are becoming circular

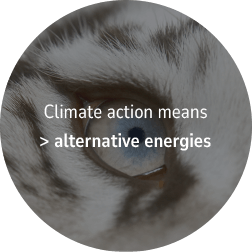

The indirect role we play towards protecting the climate is just as important as our direct activities. The circular economy helps companies to consider the whole lifecycle of their products – working backwards from the end of their useful life so to speak – so that preferably 100% of the contents can be recovered for reuse.

This approach – known as ecodesign or design for recycling – is vital if we wish to find a way out of the blind alley the linear economy is taking us down, with its looming shortages of natural resources and ongoing damage to our climate.

This goal can only be reached if everyone works together: the manufacturing industry, the circular economy and politicians. Producers need our advice to be able to assess what combination of contents can be used so that they can be recovered and recycled at a later date.

And, looking at the overall picture, we need politicians to set the right guidelines and incentives to make the whole idea of ecodesign more interesting for manufacturers. It goes without saying, of course, that material lifecycles must be freed of any substances that may be harmful to people’s health and/or the environment.

Even if it doesn’t look like it here. Climate change is most certainly not a reason for sloths to start celebrating. Many of the regions they live in suffer from long droughts. The green treetops wither away and the sloths can no longer use them as a source of food and fluid.

Ecodesign – the starting point for a well-functioning circular economy

What’s important right now

Growing engineering expertise

Future engineering courses must focus far more on the use of recycled raw materials and on the design of products, which must become much easier to take apart once they reach the end of their useful life.

Strengthening Germany’s innovative role

Germany must reclaim its position as market leader in the areas of technology and development – in particular, regarding patents in the recycling sector.

Raising producer awareness

The manufacturing industry must recognise ecodesign and material flow management as being one of their own fields of activity and see themselves as being a partner of the circular economy.

We do what we can. But even the most modern recycling processes are hitting a brick wall when it comes to composite materials. The use of fibreglass-reinforced plastics (FRP) and Co should be reduced to an absolute minimum to protect the environment and curb climate change.

Closing loops with REMONDIS’ support

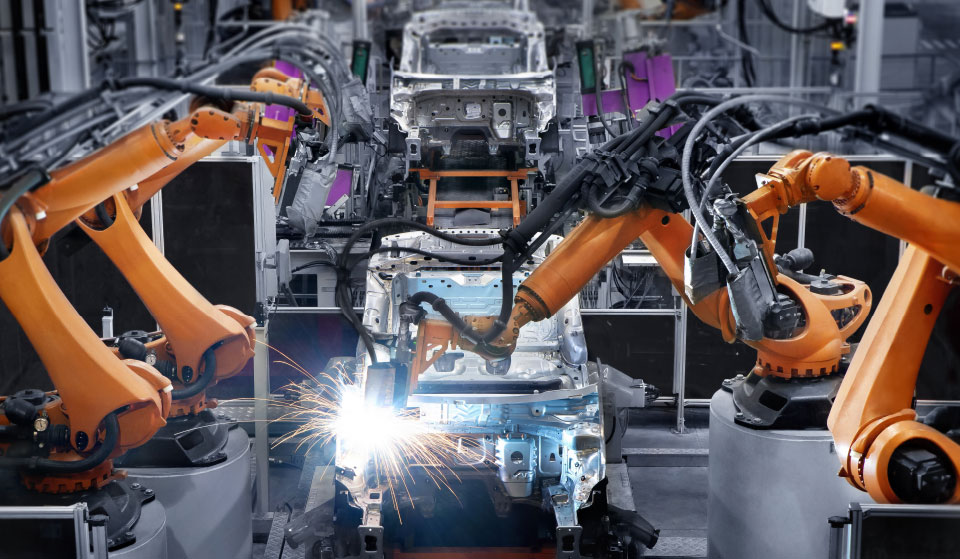

In keeping with the motto “Don’t just talk, act!”, we advise many different companies on how to close material lifecycles in their production processes. Just one example of many is the work we have been doing to promote the circular economy within the automobile industry. Being Germany’s biggest industry, it is also one of the sectors with the greatest potential to save raw materials and tackle climate change.

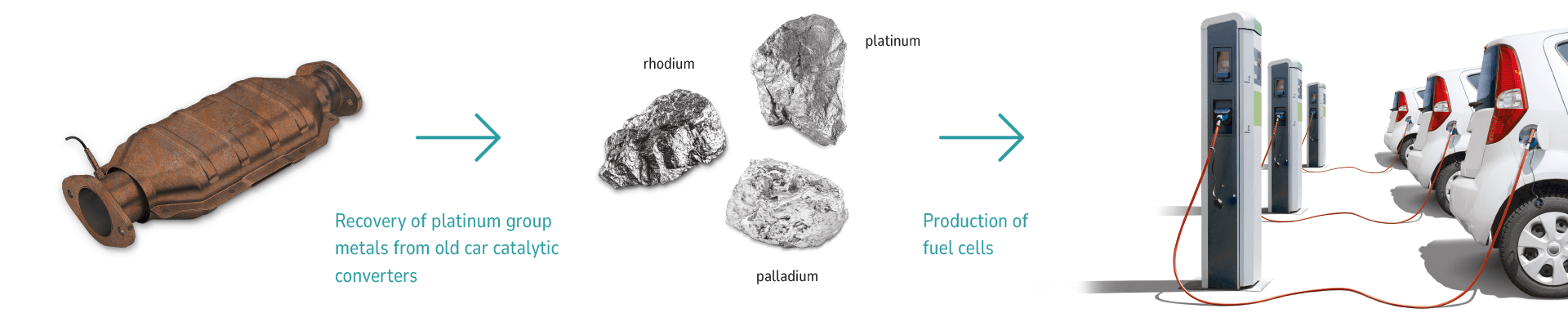

We have collaborated with car manufacturers to develop a sustainable material flow strategy that enables platinum group metals to be recovered from old automotive catalytic converters so that they, in turn, can be used to produce fuel cells. We have, therefore, not only closed a material lifecycle but also helped the automobile sector on its way to becoming a provider of climate-friendly mobility.

Cascade use within the automobile industry

So very far away from industry. And yet an excellent role model for closed loop systems. The way nature in general, and tropical rainforests in particular, use their resources is exemplary. A perfect nutrient cycle ensures that all the plants always get what they need to grow – no matter whether they’re down on the ground or high up in the trees.

There are many facets to climate action –

continued use is sometimes one of them

Working within the circular economy, we find ourselves regularly facing new recycling challenges. This means that we are constantly having to come up with new ideas that enable us to make the most of discarded consumer goods and industrial products and that are, of course, climate compatible. This does not always involve recovering the raw materials straight away. Protecting the climate and raw materials also includes extending the service life of products.

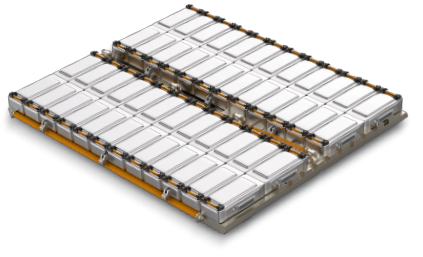

An example of how this works can be found at the Lippe Plant, which is home to the world’s largest second-use storage unit for electric car batteries. This joint project between the automobile, energy and recycling industries is making the most of the fact that these batteries still have a residual capacity even though they are no longer able to power electric cars. 1,000 individual batteries have been incorporated into the storage unit that helps to level out any dips in the national grid.

As we transition towards renewable energies renewable energies with wind, which does not always blow, and sun, which does not always shine, this storage unit plays an essential role in securing continuity of supply. And, therefore, in helping to achieve the energy switch which is vital for curbing climate change. At some stage, however, the batteries will have lost so much storage capacity that they can no longer be used in the storage unit. Solutions will need to be found here as well so that the materials contained in the batteries can be removed and separated from each other. With the number of discarded electric car batteries expecting to reach the millions in the future, our industry is working flat out to develop solutions that will enable the lifecycles of the individual materials to be systematically closed.

Further ideas and measures promoting climate-compatible recycling processes can be found at remondis-sustainability.com