Still

life

„It makes your snorkel stick in your throat. Large numbers of coral reefs are dying due to ocean acidification – unique biotopes are being irreparably damaged. This alone is reason enough to tackle climate change. For example, by systematically recycling materials.“

Özlem

Material lifecycles instead of vicious circles

The linear economy is the key driver of climate change. The common practice of continuously mining virgin raw materials and discarding them at the end of their useful life is not only leading us up a blind alley because supplies are slowly but surely running out. It also creates huge volumes of carbon emissions. Volumes that are continuing to rise.

The world’s population will have reached 10 billion people by 2050. And, every year, these people will consume 140 billion tonnes of minerals, ores, fossil fuels and biomass. Every single gram of these materials is linked to climate-damaging emissions.

On the other hand, there is also a great potential in these 140 billion tonnes to reduce emissions. Provided, of course, that as many of these raw materials as possible are supplied by the recycling sector. And this is the task that the circular economy has set itself.

Take a look at the study What a Waste 2.0 (PDF)

Clownfish live in sea anemones and are just one example of the victims of climate change. Ocean warming is bleaching their anemones and studies have shown that this is having a negative impact on clownfish. Scientists have discovered that bleaching leads to an increased production of stress hormones. And lowers their level of sexual hormones. Fewer and fewer clownfish are breeding.

Why recycling is so important for curbing climate change

A virgin raw material must be extracted from the ground using energy-intensive operations and often has to be imported from faraway countries and undergo industrial treatment before it can be used to make a product. Each of these individual steps creates emissions. And, in the case of a linear economy, the whole process starts again after the products have been sent to landfill or incinerated.

If, however, the raw materials can be recovered from the products and reused in industrial processes, then this will considerably improve a product’s climate footprint. And its material footprint as well by the way.

Find out all about recycled raw materials

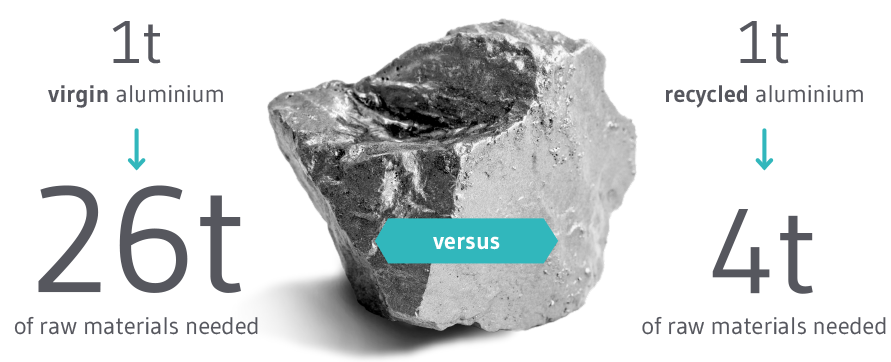

26 tonnes of raw materials are needed to produce one tonne of virgin aluminium. This figure lies at just four tonnes for one tonne of recycled aluminium.1

Every year, Europe’s materials recycling operations save over 100 million MWh of primary energy – the equivalent of the average amount of electricity consumed by around 32 million private households.2

The circular economy: the recycling champions

The circular economy’s recycling activities play a particularly valuable role in tackling climate change as they process all kinds of materials. From paper to wood, from plastic to metal, from biomass to glass – we recover all types of raw materials wherever they may be found.

This holistic approach guarantees that the very most is made of this potential to cut both carbon emissions and the consumption of raw materials. It is also yet another reason why our industry is one of the most powerful means of curbing climate change alongside the energy and transport sectors.

Germany and Europe would be wise not to waste this potential. If they do not make the most of this opportunity, they are not only in danger of failing to achieve their goals but also of losing their role as global leaders spearheading the battle against climate change. China, for example, is well aware of the potential of recycling and is in the process of systematically setting up effective structures. 30% of the steel produced in the country will soon be made using scrap steel. This single measure alone will reduce its carbon emissions by four percent!

The amount of energy saved by recycled raw materials (maximum value per tonne of recycled material used); Source: Statusbericht Kreislaufwirtschaft [Status Report of the German Circular Economy] 2020

So very beautiful but so very much at risk. Mountain glaciers are steadily melting away. And things are hardly better at the polar ice caps. The Arctic sea ice alone is shrinking at a rate of 4,756 tonnes a second.

Maximising climate action potential

At present, a mere 15% of the raw materials used in production processes in Germany are supplied by the recycling sector3. There is absolutely no good reason for this reluctance to use this climate-friendly resource as the quality of recycled raw materials is the same as that of virgin raw materials. Manufacturers are either not willing or not prepared to use them. And it is the world’s climate that is losing out here.

CO2 emissions could be reduced by 60 million tonnes simply by doubling the amount of recycled raw materials deployed in production processes to 30% – which in itself is still a low figure.3 To paint a clearer picture: that is roughly the same contribution made by the whole of the wind energy sector in 2016.4

Our goal is to take action ourselves to curb climate change as well as to get others to join in

1 Fraunhofer study: Quantifying the resource savings delivered by recycling, 2015

2 BDE et al.: Statusbericht der deutschen Kreislaufwirtschaft [Status Report of the German Circular Economy], 2018

3 www.recyclingmagazin.de/2019/10/09/kreislaufwirtschafts-potenziale-fuer-klimaschutz-erschliessen

4 Bundesverband WindEnergie: www.wind-energie.de/themen/mensch-und-umwelt/klimaschutz/